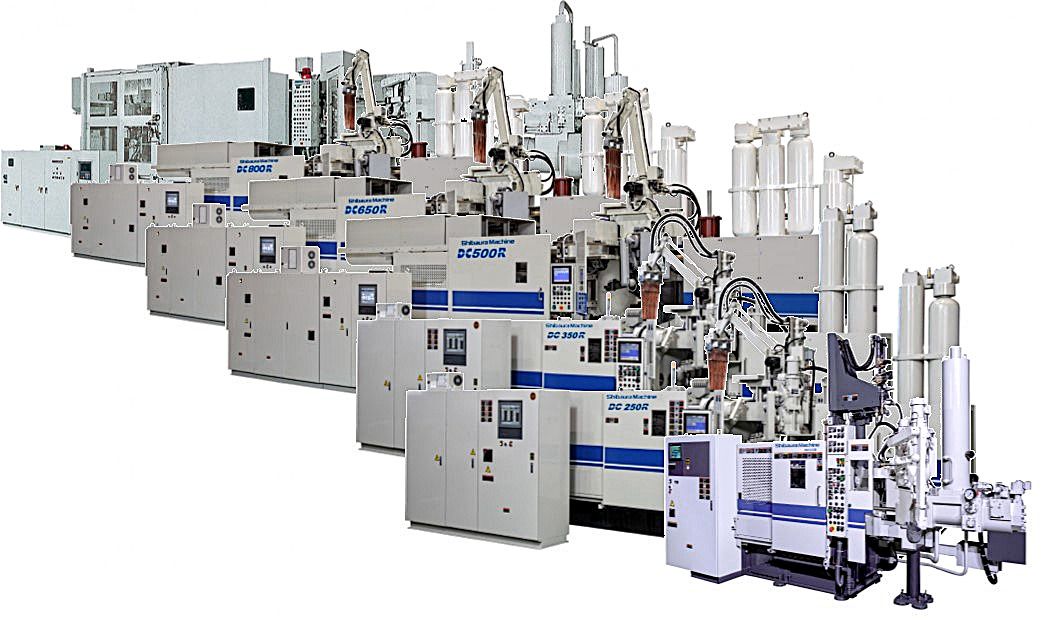

Die Casting Machines

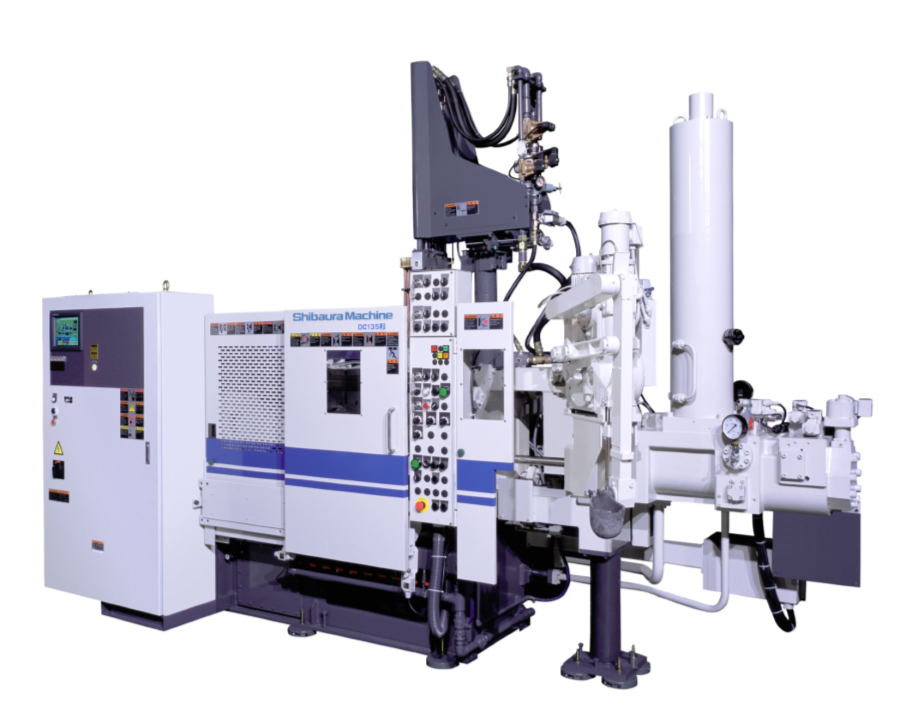

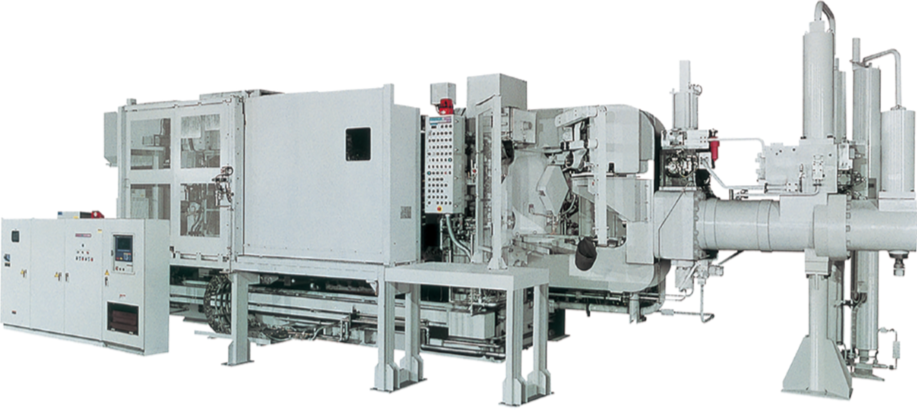

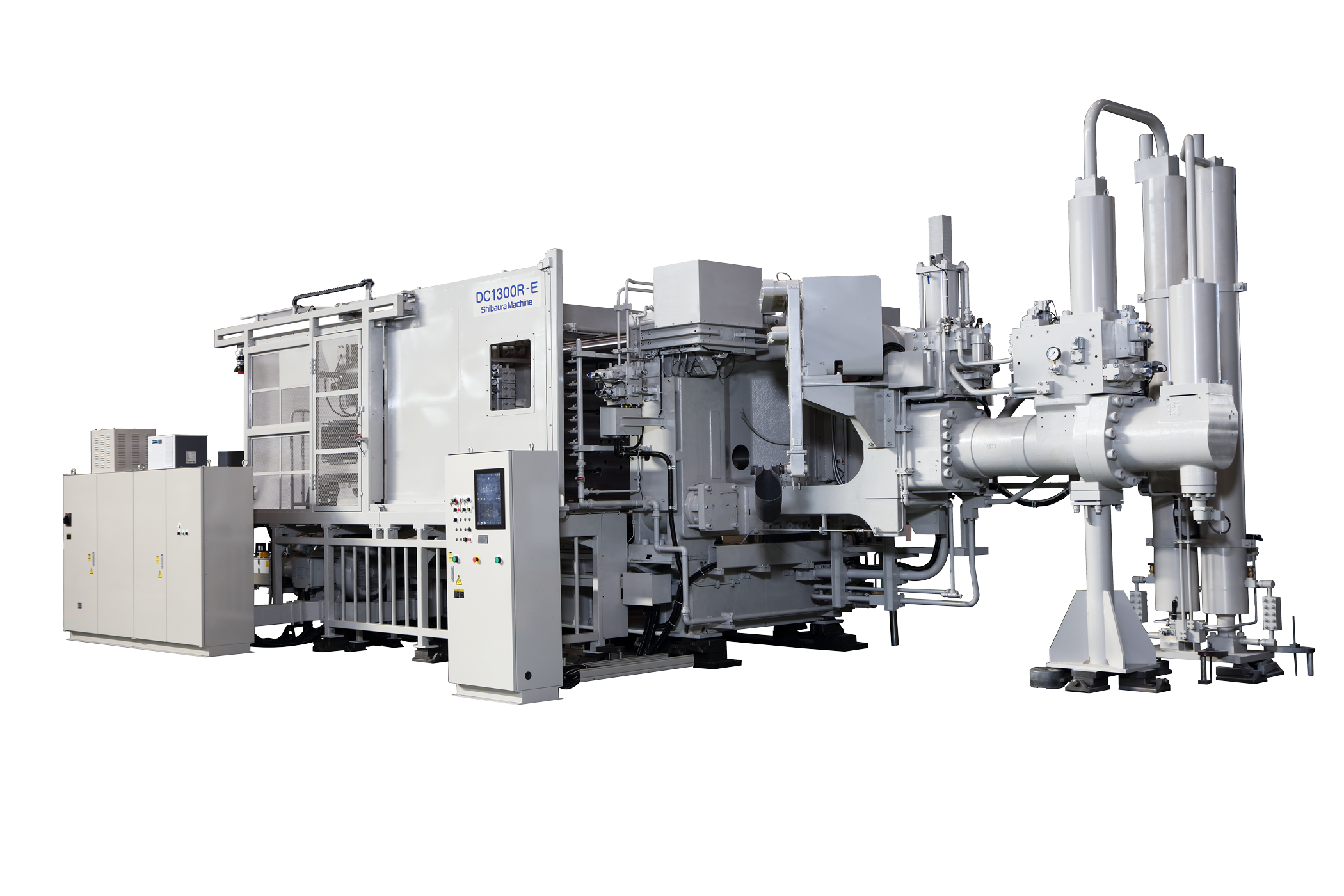

Shibaura Machine is a leading global supplier of HPDC, high pressure, cold chamber, semi-solid metal aluminum and magnesium die casting machines from 1350 to 35000 kN tons with servo hydraulic injection. Our North American headquarters, centrally located in Elk Grove Village, IL, is fully equipped to support sales, service, parts, and customer training.

We have provided over 1500 High Pressure Die Casting machines to the North American market since 1975. Our global manufacturing and world-class engineering capability, along with our long heritage of industry leading innovation, reliability, and precision, continue to make us the most proven and reliable partner for your die casting machinery needs.

Our full spectrum of machines fulfills three performances demanded of die casting machines: operational ease, fast cycle, and high-quality shots for thin wall and structural casting.

Small Size Die Casting Machines

View All

Medium Size Die Casting Machines

View All

Large Size Die Casting Machines

View All

E-Series

View All

Review all Die Casting Machines

View AllOur machine tonnage covers: 100, 250, 300, 350, 400, 450, 500, 550, 600, 650, 700, 750, 800, 850, 900, 950, 1000, 1500, 2000, 2500, 3000, 3500, and above metric and US tons.

Manufacturing solutions for wide range of applications

Die Casting Articles Die Casting Articles

Customer Care

Parts

Over our past 46 years in North America we have learned even the best machines require quick and reliable parts support. With an installed machinery base of more than 25,000 machines in the Americas, Shibaura Machine maintains a large spare parts inventory, currently more than US$15,000,000, primarily in our Chicago-area parts warehouse, but with additional stocking locations in the USA, Canada, Mexico, and Brazil.

Training Training DC

SMA 101 – Introduction to Shibaura Die Casting Machines

This course serves as an introduction to Shibaura Die Cast Machines for Die Casting Safety, Preparation of machine, Filling of fluids, Checking of power system, Origin setting, Pressure set-up, Fill accumulator with Nitrogen gas, Starting pumps, Checking movement of clamp and ejector, injection, and tie bar system.

Upon completion of this course, the student should be able to correctly operate the die-cast machine.

SMA 102 – Casting Preparation and Production Startup

This course serves as an introduction to Shibaura Die Cast Machines and will; Review the Safety discussion from SMA 101, Toscast 888 instructions, Pressure set-up, Casting set-up, core, Injection input data, Ladle, Sprayer, Takeout, Mechanical, Data setup, First shot procedure, and Production part adjustments.

This course teaches a basic understanding of the required machine set up information and process parameters.

SMA 103 – Production and Basic Process Control

This course serves as an introduction to Shibaura Die Cast Machines and will; Review the Safety discussion from SMA 101, Toscast 888, Input casting set-up, cores sequence, ejection speed and distance, Die open / close position speed and pressure, injection speed, position input data, Ladler, Sprayer, Take out Program adjustment, and testing.

In this course, the student will gain a basic understanding of the die casting process as applied to machine functionality.

SMA 201 – Process Control

This course serves as an introduction to Shibaura Die Cast Machines and will; Review the Safety discussion from SMA 101, Review SMA 103, Toscast 888, Explanation quality monitoring pages setup and resulting data, 14 Casting Technology, and Explanation of general casting technology, Process Control Power Point, Presentation of variables and corrective measures.

In this course, the student will gain a more in-depth understanding of the die casting process as applied to machine functionality.

SMA 301- Machine Troubleshooting for Operators

This course serves as an introduction to Shibaura Die Cast Machines and will; Review the Safety discussion from SMA 101, review SMA 102, Toscast 888, Explanation of maintenance related pages of the system, Ladler, Sprayer, Take out Program review, and testing.

Students will be able to understand basic alarm recovery and an explanation of machine problems.

SMA 302- Troubleshooting for Maintenance Personnel

This course serves as an introduction to Shibaura Die Cast Machines will; Review Safety, Toscast 888, Explanation of maintenance related pages of the system, Ladler, Sprayer, and Take out, Program review, and testing, Basis of Machine Maintenance, Examples of Trouble in Die Casting Machine, Injection, Die Clamping, Hydraulic Components, Electrical Components, Electrical Components, Ladling unit, Spray unit, and unloading.

After this course, students will have learned alarm recovery, explanation of machine system operation, and component replacement.

Testimonials View All

"The nice thing about a Shibaura Machine is that they never have any downtime"

The Mumford Metal Casting Companies Capabilities:High Pressure Aluminum Die Casting61 HPDC aluminum machines ranging from 400-1,750 TonsHigh Pressure Zinc Die Casting4 hot chamber zinc machines up to 500 TonsMiniature Zinc Die CastingAluminum Gravity (stat...

News View All

Shibaura Machine Celebrates 47 Years in North America

ELK GROVE VILLAGE, IL, April 19, 2021 Today is the 47th anniversary of the incorporation in Illinois of Shibaura Machine Company, America (formerly known as Toshiba Machine). It also marks our first full year under our new name, Shibaura Machine, which was...

Read moreNew Year, New Initiatives: Message from Shibaura Machine

ELK GROVE VILLAGE, IL, January 4, 2021 Upon reflection, the health and financial challenges faced by our company, nation, and the world as a whole in 2020 have been unprecedented, at least within living memory. I am extremely proud to report our managemen...

Read moreShibaura Machine - Supporting critical manufacturers in the battle against COVID-19

ELK GROVE VILLAGE, IL - April 16, 2020 – Shibaura Machine is proud to work with our customers who have been deemed “essential manufacturers” during the current COVID-19 crisis. We continue to ship out machines being used to make Personal Protective Equipm...

Read moreShibaura Machine - Services Remain Open During COVID-19

We continue to actively monitor and adopt to CDC guidelines, as well as those issued by federal, state, and local authorities to keep our staff, customers, and business partners healthy!Attached for your reference is a letter from our President and a hando...

Read moreToshiba Machine is now Shibaura Machine

ELK GROVE VILLAGE, IL April 1, 2020 – Effective April 1, 2020, our company name changed from “Toshiba Machine Company, America” to “Shibaura Machine Company, America.” We started business as a machine tool manufacturer in 1938 under the Shibaura name, and...

Read moreShibaura Machine Company, America doubles its footprint in Midwest

ELK GROVE VILLAGE, IL, June 15, 2018 - The U.S. Injection Molding Div. of Shibaura Machine completed its move into a 58,000 square foot facility in Elk Grove Village, Ill., replacing a a smaller facility in Elgin, Ill. The new plant consolidates the inject...

Read moreFAQ

Do you offer Preventive Maintenance services?

Yes, We can provide a scheduled PM service call on your machines.

Please contact dc-svc@Shibaura-Machine.com for more information.

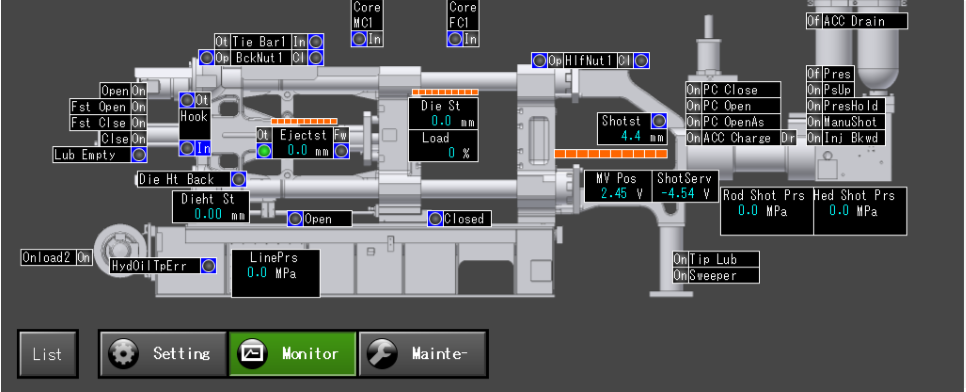

Can I get my older Toscast control updated?

We can propose an upgrade to our latest controller.

Please contact dc-svc@Shibaura-Machine.com for more information.

Do you offer training?

We offer a variety of training classes.

Click here to see our training offered.

Is integration with auxiliary equipment available?

Yes, while Shibaura Machine offers its own integrated equipment, we can also offer and integrate third-party equipment.

Speak to your Shibaura representative for details.

Does Shibaura Machine offer financing options?

Yes, our in-house financing arm, TMAC offers a variety of flexible financing solutions.

Do you have data collection software?

Yes, we have dPAQET, which will collect the shot data from up to 64 machines to a central computer database.

Can we get someone from your service department to come out and inspect our machines?

Yes

Please contact dc-svc@Shibaura-Machine.com for more information.